Informative Links

- Test Fixture and MEMS Test Fixture Design

- Circuit Design

- Semiconductor Fab Equipment Design

- Instrument Design for the Chemical, Biotech and Life Sciences Industry

Portfolio of

Example Projects

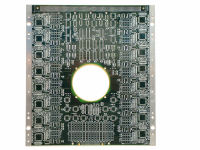

16 channel pin card PCB for a IC tester

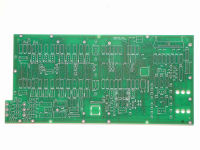

36A pulsed current driver card for high power LEDs

Front panel pcb for circuit breaker tester

Circuit Design

Circuit Design Experience

Henning Engineering has over 15 years experience designing board level electronics. A lot of our experience has been in the automated test electronic industry and custom instrumentation design.

Our board level designs have included:

- ATE Pin electronics

- Analog instrumentation such as DC meters, RMS voltmeters, calibration and reference boards, etc.

- Time and frequency measurement systems

- Relay multiplexers

- ATE Load boards

- Front panel displays

- Pulse current drivers for high power LEDs

On our designs we participate in all phases of the design process from bread boarding and prototyping on the bench up through final checkout in the final system. Extra time is spent on the layout phase to ensure that the parts placement is optimized and that critical routes are properly connected. On all our designs we aim for perfect layouts with no rework, wires, or errors and often achieve it. Our preferred layout shops have remarked that our documentation and participation in the layout process is the best they have seen.

Circuit Design Example

A recent example of our design skills was a pulse current driver we designed for a high power LED. The requirements for this project were to design a circuit to drive the LED with a forward current of 36A and be capable of operation in either CW or pulse mode. Nothing was available commercially to do this. All available LED drivers were for devices with much lower forward current specs. Our final design met all the requirements and, being true to our electro-mechanical design skills, also designed the heatsink for the LED and the related sheet metal packaging which were also part of the final product. The final design became a product that the customer manufactures by themselves and currently sells.

Additional PCB Design Techniques

Also, our unique design skills allow us to design special boards with precision alignment of the metal etch on the board to mechanical locating features such as dowel pin locating holes and other features. Our proprietary machining techniques coupled with our skill at PCB design allows us to make boards with machined features that are aligned to the metal etch with much greater precision than a normal board shop is capable of. This can be useful on certain boards used as contactors, in test fixtures, and for other specialty applications.